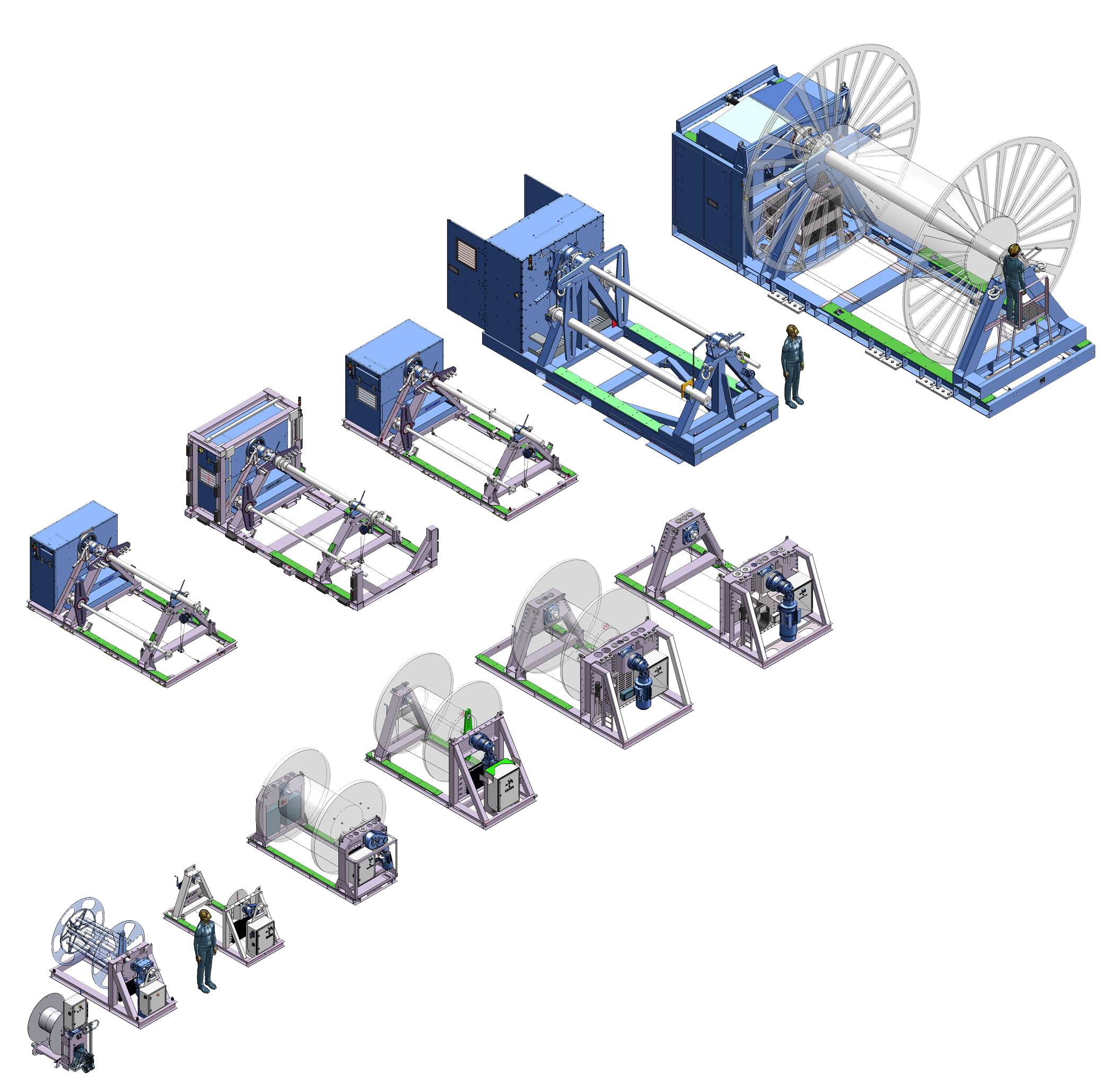

DROMEC Constant Tension machines

complete range spooling winches

DROMEC Constant Tension machines are known for their multifunctional spooling capabilities. These machines find applications in various market sectors, ranging from spooling and unspooling electrical cables to winding heavy tow wires for offshore vessels. Over the years, DROMEC has developed a diverse range of winches in terms of power and size.

Electric Drive

What makes DROMEC special is the deliberate transition to exclusively using electrically powered systems a few years ago.

According to Cees Drost,

“This transition has brought DROMEC two significant advantages. Firstly, we have reduced environmental impact by eliminating diesel emissions. Secondly, our machines can be controlled with much greater precision, allowing even highly sensitive umbilical wires to be spooled without risk, thanks to integrated data logging. Furthermore, our system offers the capability to generate electricity during the project itself. These machines are often employed in opposite position to other winches or reels, where customers require specific tension requirements. During spooling, we can switch the motor to act as a braking dynamo. This not only results in emissions savings but also energy savings, especially in situations where work is predominantly carried out indoors. In the absence of a power source at a project site, there is always the option to activate a small and energy-efficient generator, a requirement in less than 5% of projects.”

Tensioning

DROMEC primarily sees these machines being used in markets such as rigging companies, where long lengths are converted into customer-specific lengths for both steel and fiber ropes. Another application involves replacing steel cables on cranes and pile drivers, where old wires are first spooled onto an empty reel before the new or clean cable is wound under tension on the machine. DROMEC spooling machines are also widely used for wire inspection. In this process, wires are degreased, inspected, re-greased, and immediately spooled under tension on the winch, all in a single back-and-forth motion.

Customization

Upon request, DROMEC Winches can offer more extensive customer-specific features, such as Active Heave, line measurement, high-speed capabilities, or specific pulling forces. DROMEC spooling machines vary in pulling force, with the smallest machine having a pulling force of 60 kg, and the largest machine exerting a pulling force of 42 tons (at the core). For newly developed spooling machines, two essential parameters are always considered: the maximum weight of the reel within the machine and the desired pulling force. At DROMEC we are always up for this challenge!

Contact